Laser Device Maintenance 101: The Monthly Checklist to Prevent Costly Downtime

Do you know the hidden costs of ignoring your laser equipment? Regular upkeep is key to avoid unexpected downtime. This can hurt your profits a lot. In this article, we’ll look at why a laser maintenance checklist is important. It can save you both time and money.

By sticking to a simple monthly routine, you can spot issues early. This keeps your equipment running well and saves you from big problems. This way, you avoid expensive downtime and make your laser equipment last longer.

Key Takeaways

- Regular laser equipment maintenance is crucial to prevent unexpected downtime.

- A monthly checklist can help identify potential issues before they become major problems.

- Preventive maintenance can save time and money by reducing downtime.

- A well-maintained laser device operates more efficiently and has a longer lifespan.

- Neglecting maintenance can lead to costly repairs and impact your bottom line.

The Critical Importance of Regular Laser Maintenance

Regular laser machine servicing is key to avoid costly repairs. It keeps your equipment running smoothly and for longer. This way, your business can keep operating without financial loss from downtime.

The Real Cost of Laser Downtime

Laser system failures can cause big financial hits. They lead to lost production time, missed deadlines, and unhappy clients. For example, a factory using laser cutting might face a chain of delays if its system fails. This shows why laser system upkeep is so crucial.

How Preventive Maintenance Saves Money

Preventive maintenance catches problems early, saving you money. Regular cleaning and checks can spot issues before they get worse. This way, you can fix small problems before they turn into big ones, saving on repair costs. It keeps your laser system in top shape.

Building Maintenance into Your Production Schedule

Make sure to schedule maintenance into your work plan. Set aside times for upkeep that won’t disrupt your work. Planning well helps keep your productivity high while also taking care of your laser system upkeep.

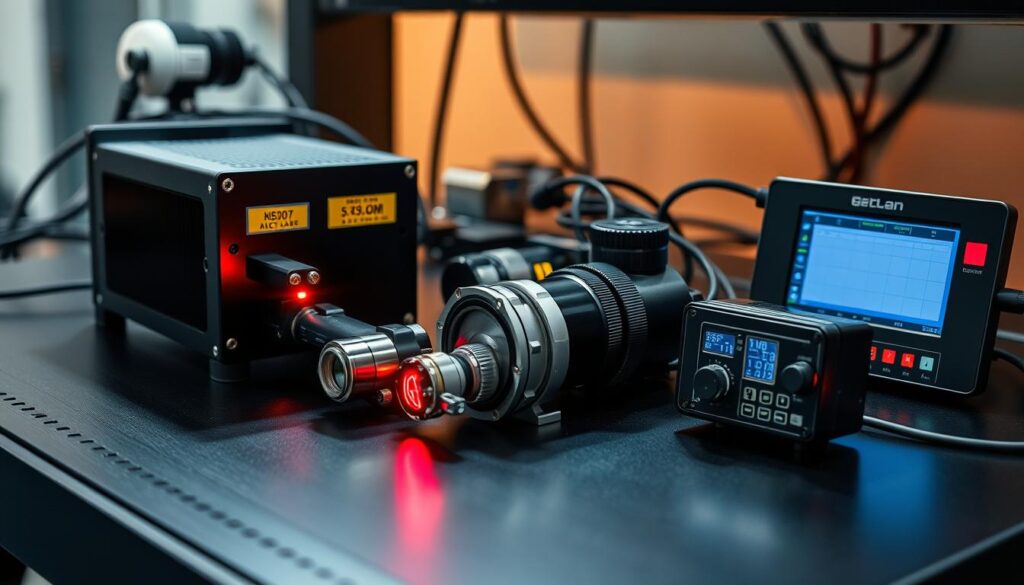

Understanding Your Laser System Components

Knowing how your laser system works is key to keeping it running well. A laser has many parts, each important for its function.

Optical Components and Their Vulnerabilities

Parts like mirrors and lenses are crucial for the laser’s beam quality. They can get damaged or dirty, affecting the laser’s performance. It’s important to clean and check them often for laser equipment care.

Mechanical Systems That Require Regular Attention

The mechanical parts of a laser can wear out over time. Keeping them well-lubricated and aligned helps them last longer.

Electrical and Cooling Systems Overview

The electrical system powers the laser, and the cooling system keeps it from overheating. Both are essential for the laser’s operation.

Power Supply Maintenance

Checking the power supply regularly is crucial for stable operation.

Cooling System Checks

Keeping the cooling system in good shape means checking for leaks and ensuring the coolant is at the right level.

By taking care of these parts, you can make your laser device more reliable and efficient. This follows the idea of preventive maintenance for lasers.

Laser Device Maintenance101: The Monthly Checklist That Prevents Costly Downtime

To keep your laser device running smoothly, you need a regular maintenance plan. We’ll show you how to do it. This monthly checklist helps avoid unexpected downtime and keeps your laser working at its best.

Week 1: Optical System Inspection and Cleaning

The optical system is key to your laser’s performance. First, check the mirrors’ alignment and lenses for damage or dirt.

Mirror Alignment Verification

Make sure all mirrors are aligned right. This ensures the laser beam is accurate. If not, it can cause performance issues and wear out other parts.

Lens Inspection Procedures

Look for wear, damage, or dirt on lenses. Clean or replace them if needed to keep the beam quality high.

Week 2: Mechanical System Checks

The mechanical parts of your laser are just as crucial. Focus on lubricating moving parts and checking belt tension and wear.

Motion System Lubrication

Lubricating moving parts reduces friction and wear. This keeps your laser running smoothly and lasts longer.

Belt Tension and Wear Assessment

Check belts for the right tension and wear. Adjust or replace them to avoid mechanical failures.

Week 3: Electrical and Cooling System Verification

The electrical and cooling systems are vital for your laser’s operation. Inspect wiring and connections, and check coolant levels and quality.

Wiring and Connection Inspection

Make sure wiring and connections are secure and undamaged. This prevents electrical problems and ensures safety.

Coolant Level and Quality Testing

Check coolant levels and test its quality. Add or replace coolant as needed to keep cooling effective.

Week 4: Performance Testing and Calibration

End with performance testing and calibration. This includes checking power output and analyzing the beam profile.

Power Output Measurement

Measure the laser’s power output to ensure it’s correct. Adjust settings or perform maintenance if needed.

Beam Profile Analysis

Analyze the beam profile to check its quality and characteristics. This helps spot any performance issues.

By sticking to this monthly checklist, you can keep your laser device in great shape. This minimizes downtime and ensures optimal performance.

Essential Tools and Supplies for Laser Maintenance

To keep your laser system in top shape, you need the right tools and supplies. Good maintenance ensures it works well and saves money on repairs.

Cleaning Materials and Solutions

Cleaning is key for laser upkeep. You’ll need specialized cleaning solutions and lint-free cloths to avoid damage. Don’t use regular cleaners or cloths that can leave marks or residue.

Diagnostic Equipment

Diagnostic tools are vital for spotting problems early. Use beam profilers and power meters to check the laser’s health and catch any issues.

Safety Equipment Requirements

Always prioritize safety when working on lasers. Make sure you have laser safety glasses and protective gloves to prevent accidental exposure.

Maintenance Documentation Tools

Keeping detailed records of maintenance is important. Use maintenance logs and digital documentation tools to track your work and plan for the future.

| Tool/Supply | Description | Importance Level |

| Specialized Cleaning Solutions | For cleaning optical components | High |

| Beam Profilers | For monitoring laser beam quality | High |

| Laser Safety Glasses | For protecting against laser exposure | High |

| Maintenance Logs | For recording maintenance activities | Medium |

With these essential tools and supplies, you’re ready to handle routine maintenance. Your laser system will stay in great condition.

Step-by-Step Guide to Optical Component Maintenance

Keeping your laser device’s optical parts in good shape is key. These parts, like mirrors, lenses, and the beam delivery system, are essential for the laser’s work. Regular upkeep helps your laser run smoothly, avoiding expensive repairs.

Inspecting and Cleaning Mirrors

Mirrors are crucial and need special care. It’s important to inspect and clean them right to avoid damage.

Proper Mirror Removal Techniques

When you take mirrors out for cleaning, wear gloves. This stops oils from your skin from touching the mirror. Always follow the maker’s guide for removal.

Cleaning Solutions and Methods

Choose a cleaning solution that the maker suggests. Gently clean the mirror with a soft cloth, avoiding anything that might scratch it.

Lens Maintenance Procedures

Lenses, like focus lenses and beam expanders, need careful handling. This keeps them working well.

Focus Lens Care

Check focus lenses often for any damage or dirt. Clean them as advised to keep the coating safe.

Beam Expander Maintenance

Beam expanders need to be checked for alignment and cleanliness. Make sure everything is tight and free of dust.

Beam Delivery System Upkeep

The beam delivery system, including bellows, tubing, and nozzles, needs regular checks and care.

Bellows and Tubing Inspection

Look for wear or damage on bellows and tubing. Replace any bad parts to avoid beam problems or contamination.

Nozzle Cleaning and Replacement

Keep nozzles clean to stop blockages. Replace them when the maker says to for the best results.

Troubleshooting Common Laser Issues Before They Cause Downtime

Fixing laser problems early is key to avoiding downtime. Spotting early signs and fixing small issues quickly stops big problems from happening.

Recognizing Early Warning Signs

Laser systems often show signs of trouble before they stop working. Knowing these signs is important for keeping things running smoothly.

Changes in Beam Quality

A change in beam quality means something’s wrong with the optics or alignment. Regular checks can catch these problems early.

Unusual Sounds or Vibrations

Strange sounds or vibrations mean there’s a mechanical problem. Not fixing these can lead to bigger issues.

Quick Fixes for Minor Problems

Some problems can be fixed with simple tweaks or parts swaps. Knowing how to do these fixes can save a lot of time.

Realignment Procedures

Realignment is needed if the laser beam isn’t hitting the right spot. This step needs precision and care.

Filter Replacement

Filters are key to keeping the laser system clean. Replacing them regularly is vital for the best performance.

When to Call in Professional Service

Some issues need a pro’s touch. Knowing when to ask for help is important to avoid more damage.

Critical System Failures

For major system failures, you need a pro to get things working again. These failures can have big effects if not fixed fast.

Scheduled Professional Maintenance

Regular maintenance by pros keeps your laser system running at its best. Scheduling these visits can prevent unexpected problems.

Conclusion: Implementing Your Laser Maintenance Program

Regular maintenance is key for laser devices to work their best. Having a laser maintenance schedule is not just a good idea. It’s essential to avoid expensive downtime and keep your equipment lasting longer.

Preventive maintenance for lasers includes several checks and steps we’ve talked about before. By sticking to this plan, you can lower the chance of sudden failures. This helps keep your laser’s quality high.

Make sure to add the monthly checklist to your work schedule. This way, laser maintenance becomes a regular part of your work. This approach will save you money and boost your productivity and efficiency over time.

By managing your laser device’s maintenance, you’re investing in your business’s future. Stay one step ahead of problems. Keep your laser devices performing at their peak.

FAQ

How often should we perform laser device maintenance?

We suggest doing laser device maintenance every month. Use a checklist to avoid expensive downtime and keep things running smoothly.

What are the consequences of neglecting laser maintenance?

If we ignore laser maintenance, performance drops. This increases the chance of equipment failure and leads to costly downtime. It can mess up our production schedule and hurt our profits.

What components of a laser system require regular maintenance?

The optical, mechanical, electrical, and cooling systems need regular checks. This ensures the laser works well and efficiently.

How do we inspect and clean optical components?

We clean mirrors and lenses with special materials and solutions. We use the right techniques to avoid damage.

What diagnostic equipment is necessary for laser maintenance?

Tools like power meters and beam profilers are key. They help us check the laser’s performance and spot problems early.

How can we troubleshoot common laser issues?

We tackle common laser problems by spotting early signs, like changes in beam quality or odd sounds. Quick fixes, like realignment or replacing filters, can solve issues before we need professional help.

What are the benefits of implementing a laser maintenance program?

A laser maintenance program saves us money and time. It prevents costly downtime, cuts repair costs, and keeps our equipment running at its best.

How can we minimize repair costs for our laser devices?

Regular preventive maintenance and quick action on issues help. Following a maintenance schedule also prevents equipment failure, saving us money in the long run.